About Us

Truck Brake Chamber: A Core Component Ensuring Driving Safety

Views : 264

Update time : 2025-07-24 15:48:00

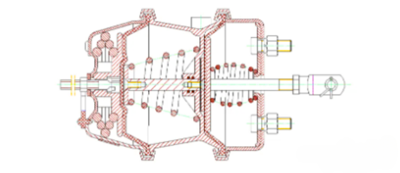

The truck brake chamber is a key executive device in the pneumatic braking system. It converts mechanical energy through compressed air, drives the braking components to realize vehicle deceleration or parking, and is directly related to driving safety.

Types

- Diaphragm type: With a rubber diaphragm as the core elastic element, it has a simple structure, low cost and convenient maintenance. It is widely used in medium and small trucks and trailers.

- Piston type: Using piston and spring as core components, it has better sealing performance, larger and more stable output thrust, and is suitable for heavy trucks, engineering machinery and other vehicles with high requirements for braking performance.

Working Principle

The working process of the truck brake chamber can be divided into three stages:

- Brake triggering: When the driver steps on the brake pedal, the air pressure control valve opens, and compressed air enters the brake chamber through the pipeline.

- Force conversion: The diaphragm or piston in the brake chamber deforms under the action of air pressure, overcomes the elastic force of the return spring, and pushes the push rod to extend outward.

- Brake execution:

①The push rod drives the brake cam to rotate (or pushes the brake caliper) through the brake lever, making the brake pad closely fit with the brake drum (or brake disc), generating braking torque to realize vehicle braking.

②When the brake pedal is released, the compressed air in the brake chamber is discharged, and the return spring resets the diaphragm or piston, the push rod retracts, and the brake is released.

Importance and Common Faults

The performance of the brake chamber directly affects the braking effect of the truck:

- Core guarantee for driving safety: A high-quality brake chamber can ensure that the vehicle decelerates quickly and stops smoothly under heavy load, high speed or complex road conditions, avoiding accidents such as rear-end collisions and rollovers.

- Common faults and hazards: If the brake chamber has problems such as diaphragm rupture, air leakage, and push rod jamming, it will lead to slow braking, insufficient braking force or even brake failure, which seriously threatens driving safety. In addition, fatigue fracture of the return spring may cause brake drag, aggravate brake pad wear and increase fuel consumption.

Daily Maintenance and Purchase

To extend the service life of the brake chamber and ensure its performance, daily maintenance should pay attention to:

- Regularly check the tightness of the brake chamber, and observe whether there is air leakage or oil seepage;

- Check whether the push rod stroke is within the standard range to avoid abnormal braking due to jamming;

- Timely replace aging vulnerable parts such as diaphragms and springs, and select accessories that meet the original specifications.

When purchasing, priority should be given to well-known brand products to ensure that their material strength, sealing performance and output thrust meet industry standards. Especially for heavy trucks, it is necessary to match the brake chamber model suitable for the vehicle load and power.

In short, although the truck brake chamber is small, it is a "key link" to ensure road traffic safety. Only by attaching importance to its daily maintenance and scientific purchase can every transportation be safe and reliable.

Related News

Revealing Three Little-Known Facts About Trucks

Revealing Three Little-Known Facts About Trucks

Aug 06,2025

This article presents three little-known facts about trucks, including that the cab can be flipped for engine maintenance, the rearview mirrors are equipped with defrosting and deicing functions, and the small tank next to the fuel tank is an urea tank which is crucial for environmental protection. It helps readers understand the secrets behind truck designs and functions.

Control Valve: The "Key Steward" in Truck Engines

Control Valve: The "Key Steward" in Truck Engines

Aug 05,2025

This article introduces the role of the control valve in the diesel pump, including controlling fuel quantity and stabilizing pressure; lists symptoms when it malfunctions, such as weakened power and increased fuel consumption; provides maintenance methods, and illustrates through cases that paying attention to the control valve can avoid unnecessary expenses.

Control Valve: The "Invisible Commander" of Truck Power

Control Valve: The "Invisible Commander" of Truck Power

Aug 05,2025

The control valve is an indispensable core regulating component in the truck power system. Although it hides inside the machinery and keeps a low profile, it relies on its powerful functions to precisely command the rhythm of power output, comprehensively ensure driving safety, and intelligently adapt to various working conditions. With sophisticated design techniques and durable material selection, it can achieve a perfect balance between power and efficiency in various complex scenarios, and can be called the invisible cornerstone supporting the efficient and stable operation of trucks.

Truck Snow Chains: Safety Guarantee on Icy and Snowy Roads

Truck Snow Chains: Safety Guarantee on Icy and Snowy Roads

Jul 28,2025

This article elaborates on truck snow chains, including their important role on icy and snowy roads, applicable scenarios, selection methods, installation steps, and usage precautions. It aims to provide references for truck drivers to drive safely in icy and snowy weather and reduce accidents caused by slippery roads.