About Us

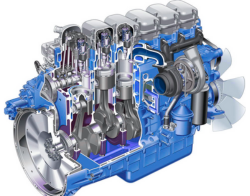

Truck Diesel Engine: The Powerhouse of Heavy-Duty Transportation

Views : 186

Update time : 2025-07-18 11:13:49

Working Principles of Truck Diesel Engines

(1) Four-Stroke Cycle Operation

- Intake Stroke: The piston moves downward, the intake valve opens, the exhaust valve closes, and pure air enters the cylinder. The pressure at the end of the intake stroke is approximately (0.85-0.95) p0, and the temperature is 300-340K.

- Compression Stroke: Both valves are closed, the piston moves upward to compress the air, with a compression ratio of 16-22. The pressure at the end is 3000-5000kPa, and the temperature is 750-1000K, far exceeding the auto-ignition point of diesel (about 520K).

- Power Stroke: At the end of compression, the high-pressure fuel pump injects diesel into the combustion chamber through the injector at a pressure of about 10MPa. The diesel auto-ignites, causing the pressure in the cylinder to rise sharply to 5000-9000kPa and the temperature to 1800-2000K, pushing the piston to do work, which is a compression-ignition method.

- Exhaust Stroke: The intake valve closes, the exhaust valve opens, and the piston moves upward to expel exhaust gas, with the exhaust temperature being 700-900K.

(2) Differences from Gasoline Engine Working Principles

Gasoline engines rely on spark plugs for ignition, mixing fuel and air before intake; diesel engines inject diesel into high-temperature air at the end of the compression stroke for compression ignition, and only inhale air. They differ significantly in compression ratio, ignition method, and mixture formation.

Structural Composition of Truck Diesel Engines

(1) Crankshaft and Connecting Rod Mechanism

- Piston: Reciprocates and transmits force to the connecting rod through the piston pin.

- Connecting Rod: Connects the piston and the crankshaft, converting linear motion into rotational motion of the crankshaft.

- Crankshaft: Converts the force from the connecting rod into torque output to drive the transmission system.

(2) Valve Train

- Valves: The intake valve controls intake, and the exhaust valve controls exhaust.

- Camshaft: Driven by the crankshaft, it controls the timing and lift of valve opening and closing to ensure proper gas exchange.

(3) Fuel Injection System

- High-Pressure Fuel Pump: Pressurizes diesel to above 10MPa for use by the injector.

- Injector: Atomizes high-pressure fuel and injects it into the combustion chamber to promote fuel-air mixing.

(4) Other Auxiliary Systems

- Cooling System: Circulates coolant to dissipate heat and maintain the engine's normal temperature.

- Lubrication System: Supplies lubricating oil to reduce wear and extend component life.

- Starting System: Provides initial power to help the engine start.

Performance Advantages and Disadvantages of Truck Diesel Engines

(1) Performance Advantages

- High Energy Density and Long Range: Diesel has a higher energy density than gasoline, allowing longer range on a single refueling, suitable for long-distance transportation.

- Strong Torque Output: Can output large torque at low speeds, providing strong power for heavy-load starting and climbing.

- Good Fuel Economy: Thermal efficiency is 30%-45%, with lower fuel consumption for the same mileage, reducing operating costs.

- High Reliability and Durability: Components have high strength, can withstand long-term high loads, have a long service life, and require less maintenance.

(2) Performance Disadvantages

- Emission Pollution Issues: Combustion produces more pollutants, harmful to the environment and human health, with high emission control costs.

- High Noise and Vibration: Generates high noise and vibration during operation, affecting comfort and the surrounding environment.

- Difficult Cold Starting: Requires compression to a sufficient temperature for ignition, making cold starting difficult, often needing preheating equipment.

- High Costs: Complex structure leads to higher purchase costs than some gasoline engines; maintenance and repair costs are also higher.

Technical Development Trends of Truck Diesel Engines

(1) Upgrading of Emission Control Technologies

- Optimization of Exhaust Aftertreatment: Using Diesel Particulate Filters (DPF) and Selective Catalytic Reduction (SCR) technologies to improve purification efficiency and meet environmental regulations.

- New Combustion Technologies: Such as the Miller cycle, which delays intake valve closing to reduce pumping losses, improve intake efficiency, and reduce emissions and fuel consumption.

(2) Development of Intelligence and Automation

- Upgrading of Electronic Control Systems: Sensors monitor operating conditions in real-time, and the Electronic Control Unit (ECU) precisely adjusts parameters to improve performance and response.

- Automatic Diagnosis and Early Warning: Automatically detects faults, alarms, and records information to facilitate quick maintenance.

(3) Integration of Hybrid and New Energy

- Diesel-Electric Hybrid: Motor-assisted driving, with the motor working during starting and low speeds, and the diesel engine intervening during high speeds and heavy loads, reducing fuel consumption and emissions.

- New Energy Exploration: Developing hydrogen internal combustion engines to reduce reliance on traditional diesel and move towards clean energy.

Maintenance Points for Truck Diesel Engines

(1) Daily Inspection

- Engine Oil: Check the level and quality, replace promptly if abnormal.

- Coolant: Check the level, and test the freezing point in cold seasons.

- Air Filter: Regularly clean or replace to ensure smooth air intake.

(2) Regular Maintenance

- Fuel Filter: Replace according to mileage to filter impurities and protect the injection system.

- Injector: Regularly inspect and adjust to ensure normal atomization and injection quantity.

- Valve Clearance: Regularly adjust to ensure proper valve opening and closing.

(3) Maintenance Under Special Working Conditions

- After Heavy Loads: Check component connections and oil/water temperatures to detect potential problems in time.

- In Low Temperatures: Preheat the engine in advance, use suitable oil and diesel to prevent starting difficulties and increased wear.

- After Severe Road Conditions: Check the engine bottom and clean radiators to prevent blockage affecting heat dissipation.

相关新闻

Revealing Three Little-Known Facts About Trucks

Revealing Three Little-Known Facts About Trucks

Aug 06,2025

This article presents three little-known facts about trucks, including that the cab can be flipped for engine maintenance, the rearview mirrors are equipped with defrosting and deicing functions, and the small tank next to the fuel tank is an urea tank which is crucial for environmental protection. It helps readers understand the secrets behind truck designs and functions.

Control Valve: The "Key Steward" in Truck Engines

Control Valve: The "Key Steward" in Truck Engines

Aug 05,2025

This article introduces the role of the control valve in the diesel pump, including controlling fuel quantity and stabilizing pressure; lists symptoms when it malfunctions, such as weakened power and increased fuel consumption; provides maintenance methods, and illustrates through cases that paying attention to the control valve can avoid unnecessary expenses.

Control Valve: The "Invisible Commander" of Truck Power

Control Valve: The "Invisible Commander" of Truck Power

Aug 05,2025

The control valve is an indispensable core regulating component in the truck power system. Although it hides inside the machinery and keeps a low profile, it relies on its powerful functions to precisely command the rhythm of power output, comprehensively ensure driving safety, and intelligently adapt to various working conditions. With sophisticated design techniques and durable material selection, it can achieve a perfect balance between power and efficiency in various complex scenarios, and can be called the invisible cornerstone supporting the efficient and stable operation of trucks.

Truck Snow Chains: Safety Guarantee on Icy and Snowy Roads

Truck Snow Chains: Safety Guarantee on Icy and Snowy Roads

Jul 28,2025

This article elaborates on truck snow chains, including their important role on icy and snowy roads, applicable scenarios, selection methods, installation steps, and usage precautions. It aims to provide references for truck drivers to drive safely in icy and snowy weather and reduce accidents caused by slippery roads.