About Us

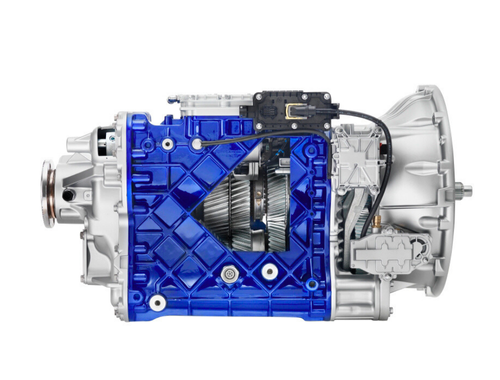

Truck Transmission: The Core Hub of Power Transmission and Technological Evolution

Views : 174

Update time : 2025-07-18 10:21:14

The Core Role of the Transmission: The "Regulator" of Power Transmission

In the power system of a truck, the transmission acts as a "power distribution center" and plays an irreplaceable role.

- The power output by the engine has a high rotational speed but relatively limited torque, which cannot directly meet the diverse needs of the vehicle such as starting, climbing, and high-speed driving.

- Through the switching of different gear combinations, the transmission can convert the engine power into torque and rotational speed suitable for different driving states.

- It not only ensures the driving force of the vehicle under heavy load or complex road conditions but also reduces the engine load during high-speed driving, achieving a balance between power and efficiency.

Main Types and Characteristics of Truck Transmissions

At present, truck transmissions are mainly divided into four categories, each with its unique advantages and applicable scenarios:

- Manual Transmission (MT)

- Advantages: Simple structure, low cost, and convenient maintenance.

- Working mode: The driver manually operates the gear lever to change gear meshing, which can accurately match the driving intention.

- Applicable scenarios: Small and medium-sized trucks and scenarios with high requirements for maneuverability, which require high driving skills.

- Automatic Transmission (AT)

- Advantages: Realizes automatic gear shifting by means of hydraulic transmission or electronic control, with convenient operation and good smoothness.

- Disadvantages: Complex structure and high manufacturing cost.

- Applicable scenarios: Mostly used in high-end heavy-duty trucks.

- Automated Manual Transmission (AMT)

- Characteristics: Modified by adding an electronic control module on the basis of the manual transmission, it has both the reliability of the manual transmission and the convenience of automatic gear shifting.

- Application: It has been increasingly widely used in long-distance freight trucks in recent years.

- Continuously Variable Transmission (CVT)

- Advantages: It can realize continuous power output and has excellent shifting smoothness.

- Limitations: Due to the limitation of torque-bearing capacity, it is currently rarely used in the field of heavy-duty trucks.

Transmission Adaptation Logic Under Different Working Conditions

Different working conditions have clear guidance for the selection of transmissions:

- Urban working conditions with short-distance distribution and frequent start-stop: AMT or AT transmissions can reduce the driver's operation intensity and improve driving efficiency.

- Long-distance trunk transportation: Manual transmissions or high-efficiency AMTs have become better choices due to their lower failure rates and fuel consumption.

- Heavy-load and low-speed scenarios such as mines and engineering: Manual transmissions with strong torque-bearing capacity or special heavy-duty ATs are more able to adapt to harsh environments.

Technical Development Trends of Truck Transmissions

With the technological innovation of the automobile industry, truck transmissions are developing rapidly towards intelligence and high efficiency:

- In terms of intelligence: The in-depth application of electronic control technology enables the transmission to automatically adjust the shifting strategy according to real-time road conditions, vehicle load, and engine status. For example, it can predict slope changes through GPS and complete shifting operations in advance to reduce power loss.

- In terms of high efficiency: The use of lightweight materials and the improvement of gear processing accuracy further reduce the running resistance of the transmission, helping trucks achieve energy conservation and emission reduction.

- New trend: The combination of hybrid technology and transmission has become a new trend. Through the cooperative work of the motor and the transmission, the motor can drive at the starting and low-speed stages, and switch to the engine direct drive at the high-speed stage, greatly optimizing fuel economy.

Key Points of Daily Maintenance for Truck Transmissions

Daily maintenance is crucial to extend the service life of the transmission:

- Oil inspection and replacement: It is necessary to regularly check the liquid level and quality of the transmission oil. Insufficient or deteriorated oil will lead to increased gear wear and shifting jams. It is generally recommended to replace the transmission oil every 60,000 - 100,000 kilometers. The specific cycle should refer to the vehicle manual.

- Driving habits: Pay attention to avoiding frequent rapid acceleration, rapid deceleration, and skipping gears to reduce the instantaneous load on the transmission.

- Targeted maintenance: For manual transmissions, it is also necessary to check the flexibility of the shifting mechanism and timely lubricate or replace worn parts; for automatic transmissions, attention should be paid to the working status of the electronic control unit to avoid shifting abnormalities caused by sensor failures.

相关新闻

Revealing Three Little-Known Facts About Trucks

Revealing Three Little-Known Facts About Trucks

Aug 06,2025

This article presents three little-known facts about trucks, including that the cab can be flipped for engine maintenance, the rearview mirrors are equipped with defrosting and deicing functions, and the small tank next to the fuel tank is an urea tank which is crucial for environmental protection. It helps readers understand the secrets behind truck designs and functions.

Control Valve: The "Key Steward" in Truck Engines

Control Valve: The "Key Steward" in Truck Engines

Aug 05,2025

This article introduces the role of the control valve in the diesel pump, including controlling fuel quantity and stabilizing pressure; lists symptoms when it malfunctions, such as weakened power and increased fuel consumption; provides maintenance methods, and illustrates through cases that paying attention to the control valve can avoid unnecessary expenses.

Control Valve: The "Invisible Commander" of Truck Power

Control Valve: The "Invisible Commander" of Truck Power

Aug 05,2025

The control valve is an indispensable core regulating component in the truck power system. Although it hides inside the machinery and keeps a low profile, it relies on its powerful functions to precisely command the rhythm of power output, comprehensively ensure driving safety, and intelligently adapt to various working conditions. With sophisticated design techniques and durable material selection, it can achieve a perfect balance between power and efficiency in various complex scenarios, and can be called the invisible cornerstone supporting the efficient and stable operation of trucks.

Truck Snow Chains: Safety Guarantee on Icy and Snowy Roads

Truck Snow Chains: Safety Guarantee on Icy and Snowy Roads

Jul 28,2025

This article elaborates on truck snow chains, including their important role on icy and snowy roads, applicable scenarios, selection methods, installation steps, and usage precautions. It aims to provide references for truck drivers to drive safely in icy and snowy weather and reduce accidents caused by slippery roads.