About Us

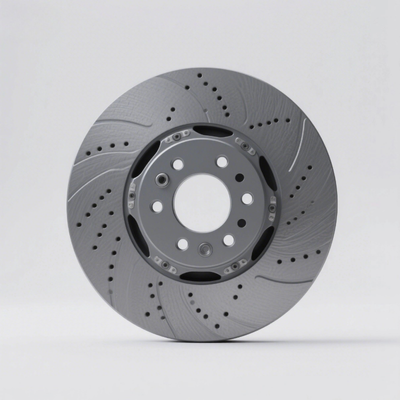

Analysis of Maintenance, Replacement and Safety Hazards of Truck Brake Discs

Views : 194

Update time : 2025-07-08 14:42:45

Maintenance Methods

Regular Cleaning: During maintenance, use a special cleaner to remove dust, oil and powder. These impurities will reduce the friction between the brake pads and the disc, avoiding affecting braking sensitivity.

Check for Wear: Inspect at least once a week. Check for scratches, cracks on the surface, and measure the thickness with a caliper. Replace it in time when the thickness is lower than the minimum thickness marked by the manufacturer (usually 15-18mm). At the same time, ensure that the gap between the brake disc and the brake pad is between 0.5-1mm.

Avoid Sudden Braking: Frequent sudden braking will cause the brake disc to heat up to more than 300℃ in an instant, accelerating the aging of the surface layer. Developing a habit of smooth driving can extend the service life by more than 30%.

Pay Attention to the Environment: Sand and gravel on muddy roads will get embedded in the disc surface and cause scratches, and stagnant water will lead to rust. Rinse with a high-pressure water gun and dry it within 30 minutes after driving.

Replace Brake Pads: When the thickness of the brake pad is only 3mm left, it must be replaced. Overly worn brake pads will scratch the brake disc like sandpaper.

Replacement Cycle

There is no fixed standard for the replacement cycle, which is affected by many factors:

- Normal road conditions (plain, light load): 100,000 - 150,000 km

- Complex road conditions (mountainous areas, heavy load, frequent braking): 80,000 - 100,000 km

The following situations require immediate replacement: cracks on the disc surface exceeding 2cm, wear groove depth > 1.5mm, high-frequency abnormal noise or body jitter during braking.

Hazards of Not Replacing in Time

Reduced Braking Performance: The braking distance is extended by more than 50% compared with the normal state, and even doubled in rainy days, which is very easy to cause rear-end collisions.

Brake Failure: Overheating causes deformation of the disc surface, which may suddenly break when climbing or descending a slope, directly losing braking capacity.

Vehicle Out of Control: Uneven wear on one side will cause braking deviation. At high speed, it can deviate more than 3 meters in 1 second.

Aggravated Wear: A damaged brake disc will shorten the service life of the brake pad by 60%, and the maintenance cost of the entire brake system will increase by 2-3 times.

Impact on Goods: Failure of emergency braking may cause goods to move forward due to inertia, causing the vehicle to roll over. When transporting dangerous goods, leakage and explosion may occur.

In short, timely maintenance and replacement of brake discs is a key line of defense to avoid major accidents.

Related News

Revealing Three Little-Known Facts About Trucks

Revealing Three Little-Known Facts About Trucks

Aug 06,2025

This article presents three little-known facts about trucks, including that the cab can be flipped for engine maintenance, the rearview mirrors are equipped with defrosting and deicing functions, and the small tank next to the fuel tank is an urea tank which is crucial for environmental protection. It helps readers understand the secrets behind truck designs and functions.

Control Valve: The "Key Steward" in Truck Engines

Control Valve: The "Key Steward" in Truck Engines

Aug 05,2025

This article introduces the role of the control valve in the diesel pump, including controlling fuel quantity and stabilizing pressure; lists symptoms when it malfunctions, such as weakened power and increased fuel consumption; provides maintenance methods, and illustrates through cases that paying attention to the control valve can avoid unnecessary expenses.

Control Valve: The "Invisible Commander" of Truck Power

Control Valve: The "Invisible Commander" of Truck Power

Aug 05,2025

The control valve is an indispensable core regulating component in the truck power system. Although it hides inside the machinery and keeps a low profile, it relies on its powerful functions to precisely command the rhythm of power output, comprehensively ensure driving safety, and intelligently adapt to various working conditions. With sophisticated design techniques and durable material selection, it can achieve a perfect balance between power and efficiency in various complex scenarios, and can be called the invisible cornerstone supporting the efficient and stable operation of trucks.

Truck Snow Chains: Safety Guarantee on Icy and Snowy Roads

Truck Snow Chains: Safety Guarantee on Icy and Snowy Roads

Jul 28,2025

This article elaborates on truck snow chains, including their important role on icy and snowy roads, applicable scenarios, selection methods, installation steps, and usage precautions. It aims to provide references for truck drivers to drive safely in icy and snowy weather and reduce accidents caused by slippery roads.