About Us

Truck Drive Shaft: The Key Link for Power Transmission

Views : 202

Update time : 2025-07-11 10:54:00

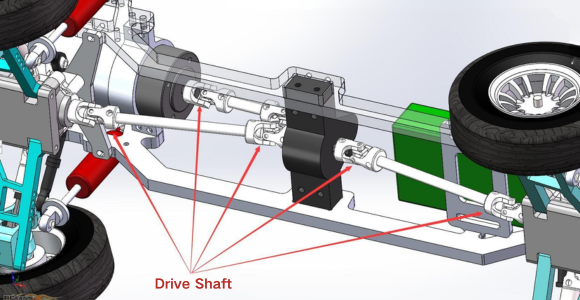

The drive shaft is the core link for power transmission in a truck. Its performance directly affects power transmission efficiency, driving stability, and reliability, ensuring that engine power is accurately transmitted to the driving wheels and enabling the truck to operate normally under various road conditions.

I. Structural Analysis

The drive shaft consists of a shaft tube, a telescopic sleeve, and a universal joint, each with clear functions:

- Shaft Tube: Made of high-strength alloy steel pipe, it bears huge torque and bending moment, providing stable support for power transmission.

- Telescopic Sleeve: Adjusts the distance change between the gearbox and the drive axle. After improvement of the traditional structure, a sealed protective sleeve and oil seal are added to enhance protection and reliability.

- Universal Joint: Like a "joint", it ensures the flexible change of the angle between two shafts to achieve constant velocity transmission, with the cross-shaft type being the most widely used. The sealing sleeve and oil seal on the outside of the drive shaft can prevent dust and rust, extending the service life.

II. Working Principle

After the engine power is shifted and torque-converted by the gearbox, it is transmitted to the drive axle through the drive shaft to drive the wheels. Due to the elasticity of the chassis suspension, the transmission distance and angle of the drive shaft will change dynamically during driving. The telescopic sleeve adjusts the distance, and the universal joint copes with the angle change, ensuring efficient and stable power transmission.

III. Common Faults and Causes

- Looseness and loud noise: A metallic impact sound when starting under heavy load or accelerating is mostly due to excessive wear of the universal joint cross shaft or telescopic sleeve beyond the limit.

- Falling off of connecting bolts: Bending of the drive shaft, unbalanced dynamic balance, loose bolts, or sudden force may cause the bolts to fall off, affecting operation.

- Vehicle shaking: Shaking at a specific speed may be caused by bending or imbalance of the drive shaft, problems with the critical speed design, or damage to the universal joint.

IV. Maintenance Points

- Regular lubrication: Timely apply grease to key parts such as the universal joint and telescopic sleeve to reduce friction and wear.

- Inspection of connecting parts: Regularly tighten connecting bolts, pay attention to the condition of the drive shaft hanger, and replace damaged parts in time.

- Proper driving: Avoid operations such as suddenly lifting the clutch, starting in high gear, and severe overloading. Some vehicles can be equipped with iron chains to prevent the hidden danger of drive shaft breakage.

V. Summary

The drive shaft is the core of power transmission. Although its structure is not complex, its maintenance should be valued. Drivers and maintenance personnel should understand its structure, principle, and fault handling, conduct daily inspections and reasonable operations, ensure the drive shaft is in good working condition, provide guarantee for the safe and efficient operation of the truck, and reduce operating costs and fault risks.

相关新闻

Revealing Three Little-Known Facts About Trucks

Revealing Three Little-Known Facts About Trucks

Aug 06,2025

This article presents three little-known facts about trucks, including that the cab can be flipped for engine maintenance, the rearview mirrors are equipped with defrosting and deicing functions, and the small tank next to the fuel tank is an urea tank which is crucial for environmental protection. It helps readers understand the secrets behind truck designs and functions.

Control Valve: The "Key Steward" in Truck Engines

Control Valve: The "Key Steward" in Truck Engines

Aug 05,2025

This article introduces the role of the control valve in the diesel pump, including controlling fuel quantity and stabilizing pressure; lists symptoms when it malfunctions, such as weakened power and increased fuel consumption; provides maintenance methods, and illustrates through cases that paying attention to the control valve can avoid unnecessary expenses.

Control Valve: The "Invisible Commander" of Truck Power

Control Valve: The "Invisible Commander" of Truck Power

Aug 05,2025

The control valve is an indispensable core regulating component in the truck power system. Although it hides inside the machinery and keeps a low profile, it relies on its powerful functions to precisely command the rhythm of power output, comprehensively ensure driving safety, and intelligently adapt to various working conditions. With sophisticated design techniques and durable material selection, it can achieve a perfect balance between power and efficiency in various complex scenarios, and can be called the invisible cornerstone supporting the efficient and stable operation of trucks.

Truck Snow Chains: Safety Guarantee on Icy and Snowy Roads

Truck Snow Chains: Safety Guarantee on Icy and Snowy Roads

Jul 28,2025

This article elaborates on truck snow chains, including their important role on icy and snowy roads, applicable scenarios, selection methods, installation steps, and usage precautions. It aims to provide references for truck drivers to drive safely in icy and snowy weather and reduce accidents caused by slippery roads.