About Us

Truck Starter: Core of the Starting System

Views : 197

Update time : 2025-07-11 10:09:33

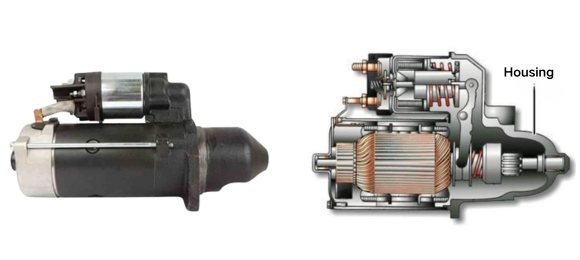

The starter is the core of the truck's starting system. It is responsible for converting the electrical energy of the battery into mechanical energy, driving the engine flywheel to rotate to start the engine. Its performance directly affects the normal operation of the truck.

I. Working Principle

Based on the operation mechanism of a DC motor, when current passes through the armature winding, electromagnetic force is generated to form torque, making the armature rotate. During operation, the DC motor rotates under the power supply of the battery, and drives the engine flywheel and crankshaft to rotate through the transmission mechanism; after the engine starts, the control device cuts off the circuit, and the starter stops working.

II. Structural Composition

- DC Motor: Mostly DC series-excited type, with coils wound with thick copper wires, which efficiently converts electrical energy into mechanical energy and provides starting power.

- Transmission Mechanism: It includes a transmission sleeve, a one-way clutch and a drive gear, responsible for transmitting power. The one-way clutch can prevent the reverse power of the engine from damaging the starter.

- Electromagnetic Switch: Composed of a switch cover assembly and a switch body, it controls the on-off of the starter circuit to ensure its timely start and stop.

III. Classification Methods

- By DC motor type: Divided into ordinary starters (traditional excitation) and permanent magnet starters (permanent magnet material magnetic poles, simple structure and high efficiency).

- By control device: There are direct-acting type (controlled by mechanical lever, laborious to operate) and electromagnetic control starters (controlled by electromagnetic force, easy to operate, widely used).

- By the meshing way of the transmission mechanism: Including inertial engagement type (gradually eliminated), forced engagement type (widely used), armature moving type, moving gear type and deceleration type (commonly used in large trucks), etc.

IV. Common Faults and Solutions

- Not working: It may be due to battery depletion, wiring problems, electromagnetic switch or motor failure, or circuit open. It is necessary to check and charge/replace the battery, clean and fasten the wiring, repair or replace faulty components, and repair the circuit.

- Idling: Mostly caused by one-way clutch slipping, gear wear or improper installation. The clutch or worn parts should be replaced, and reinstallation and adjustment should be done.

- Weak operation: Related to battery power, excessive internal resistance of the starter and large engine resistance. It is necessary to charge/replace the battery, overhaul the inside of the starter, and deal with the problem of engine resistance.

- Abnormal noise: May be caused by poor gear meshing, bearing wear, armature shaft bending or clutch damage. It is necessary to adjust the installation, replace the bearing or shaft, and repair the gear, etc.

In conclusion, understanding the principle, structure, classification and fault handling of the starter is crucial to ensuring the reliable operation of the truck. Regular inspection and maintenance are required in daily use.

相关新闻

Revealing Three Little-Known Facts About Trucks

Revealing Three Little-Known Facts About Trucks

Aug 06,2025

This article presents three little-known facts about trucks, including that the cab can be flipped for engine maintenance, the rearview mirrors are equipped with defrosting and deicing functions, and the small tank next to the fuel tank is an urea tank which is crucial for environmental protection. It helps readers understand the secrets behind truck designs and functions.

Control Valve: The "Key Steward" in Truck Engines

Control Valve: The "Key Steward" in Truck Engines

Aug 05,2025

This article introduces the role of the control valve in the diesel pump, including controlling fuel quantity and stabilizing pressure; lists symptoms when it malfunctions, such as weakened power and increased fuel consumption; provides maintenance methods, and illustrates through cases that paying attention to the control valve can avoid unnecessary expenses.

Control Valve: The "Invisible Commander" of Truck Power

Control Valve: The "Invisible Commander" of Truck Power

Aug 05,2025

The control valve is an indispensable core regulating component in the truck power system. Although it hides inside the machinery and keeps a low profile, it relies on its powerful functions to precisely command the rhythm of power output, comprehensively ensure driving safety, and intelligently adapt to various working conditions. With sophisticated design techniques and durable material selection, it can achieve a perfect balance between power and efficiency in various complex scenarios, and can be called the invisible cornerstone supporting the efficient and stable operation of trucks.

Truck Snow Chains: Safety Guarantee on Icy and Snowy Roads

Truck Snow Chains: Safety Guarantee on Icy and Snowy Roads

Jul 28,2025

This article elaborates on truck snow chains, including their important role on icy and snowy roads, applicable scenarios, selection methods, installation steps, and usage precautions. It aims to provide references for truck drivers to drive safely in icy and snowy weather and reduce accidents caused by slippery roads.