About Us

In-depth Analysis of Truck Water Pumps: A Comprehensive Insight from Principles to Maintenance

Views : 192

Update time : 2025-07-17 11:18:46

I. Introduction

As a core component of the engine cooling system, the truck water pump directly affects thermal management efficiency and engine service life. In-depth understanding of its working essence, technical details and full-cycle management is significant for equipment control, cost reduction and industry development.

II. Working Principle of Truck Water Pumps

(I) Power Drive and Energy Conversion

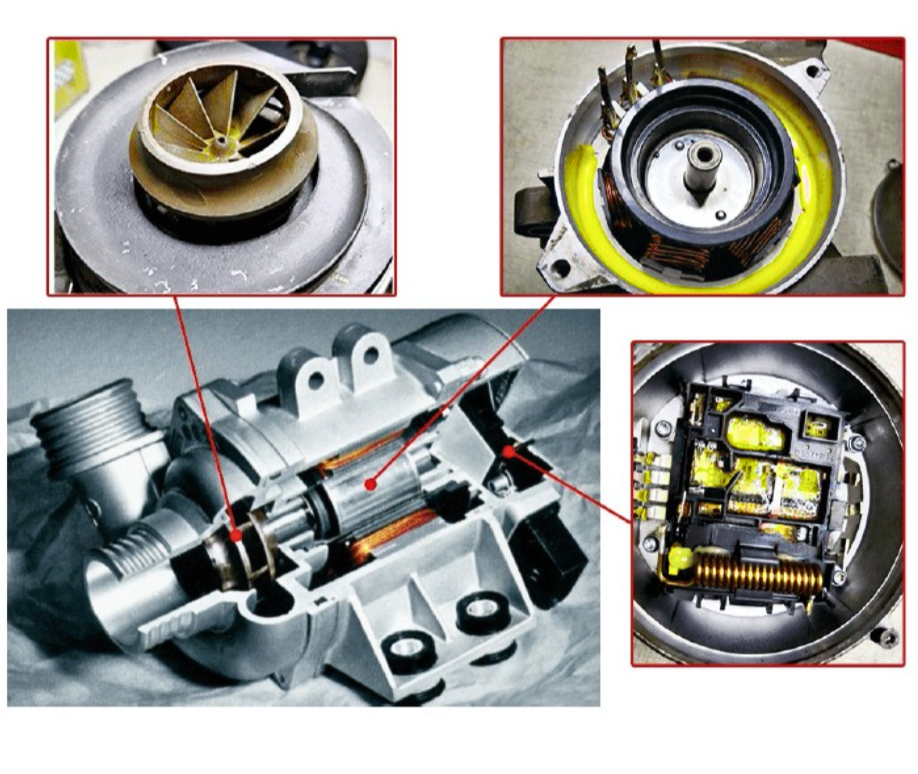

The water pump gets power from the engine via pulleys and couplings, driving the impeller to rotate. The impeller creates a centrifugal force field, moving coolant from the central low-pressure area to the edge high-pressure area, converting mechanical energy into liquid kinetic and pressure energy. Impeller blade design affects coolant flow and pressure, with fluid dynamics optimization reducing losses and improving efficiency.

(II) Dynamic Balance of Coolant Circulation

The water pump drives coolant circulation in closed loops like the engine water jacket and radiator. The thermostat works with it: closing the large cycle for quick warming during cold start; opening it for enhanced 散热 under high loads, maintaining engine thermal balance.

III. Structural Design and Technical Evolution

(I) Key Components

- Impeller: New composite impellers (e.g., carbon fiber-reinforced nylon) are lightweight and strong. Fluid simulation-designed blades reduce eddy currents, improving coolant delivery stability for high-speed and large-flow scenarios.

- Shaft Seal: From mechanical seals to dry gas and magnetic seals. Magnetic seals use magnetic fields for torque transmission, with non-contact design reducing leakage risk, suitable for high-end trucks.

(II) Water Pump Types

- Mechanically Driven: Mature, low-cost but limited by engine speed. Optimized belt tensioning mechanisms alleviate speed fluctuation impacts but may have circulation lag in complex conditions.

- Electric: Variable-frequency motor-driven, independent of engine speed, with ECU intelligent control for precise heat dissipation. Used in new energy and high-end trucks but with high integration and electromagnetic compatibility requirements, increasing power consumption and fault points.

IV. Fault Diagnosis and Root Causes

(I) Typical Faults

- Abnormal Noise: Bearing wear (due to poor lubrication or excessive tolerances) causes "buzzing"; impeller loosening (from bolt fracture or fit failure) leads to "clunking", disrupting coolant flow and increasing vibration.

- Water Leakage: Shaft seal leakage relates to coolant impurities and seal wear; pump casing cracks result from thermal fatigue and mechanical impact, reducing system pressure and affecting heat dissipation.

(II) Diagnosis Methods

- Vibration Monitoring: Acceleration sensors collect signals; spectrum analysis identifies bearing fault frequencies and impeller imbalance vibration for early warning.

- Pressure Testing: A test bench measures pressure. Abnormal drops indicate leakage or impeller damage; excessive fluctuations may mean cavitation, requiring checks on liquid level and radiator blockage.

V. Maintenance and Repair Strategies

(I) Preventive Maintenance

- Coolant Management: Select suitable coolants, test regularly. Replace long-life coolants timely to avoid component corrosion.

- Component Life: Use big data to analyze bearing and shaft seal life, establish models based on mileage and conditions, replacing components in advance to prevent faults.

(II) Repair and Renovation

- Fault Repair: Laser welding fixes pump casing cracks; plasma spraying restores worn impellers; strict shaft seal installation controls reduce secondary leakage risk.

- Remanufacturing: Retired pumps are disassembled, cleaned, repaired or with parts replaced, then tested, restoring 80%-90% performance, reducing costs and fitting the circular economy.

VI. Conclusion

Truck water pump technology involves multiple aspects. Mastering it ensures engine reliability, reduces losses and promotes technological progress. With truck intelligence and new energy development, water pumps will become more efficient, intelligent and reliable, requiring continuous industry attention and research.

相关新闻

Revealing Three Little-Known Facts About Trucks

Revealing Three Little-Known Facts About Trucks

Aug 06,2025

This article presents three little-known facts about trucks, including that the cab can be flipped for engine maintenance, the rearview mirrors are equipped with defrosting and deicing functions, and the small tank next to the fuel tank is an urea tank which is crucial for environmental protection. It helps readers understand the secrets behind truck designs and functions.

Control Valve: The "Key Steward" in Truck Engines

Control Valve: The "Key Steward" in Truck Engines

Aug 05,2025

This article introduces the role of the control valve in the diesel pump, including controlling fuel quantity and stabilizing pressure; lists symptoms when it malfunctions, such as weakened power and increased fuel consumption; provides maintenance methods, and illustrates through cases that paying attention to the control valve can avoid unnecessary expenses.

Control Valve: The "Invisible Commander" of Truck Power

Control Valve: The "Invisible Commander" of Truck Power

Aug 05,2025

The control valve is an indispensable core regulating component in the truck power system. Although it hides inside the machinery and keeps a low profile, it relies on its powerful functions to precisely command the rhythm of power output, comprehensively ensure driving safety, and intelligently adapt to various working conditions. With sophisticated design techniques and durable material selection, it can achieve a perfect balance between power and efficiency in various complex scenarios, and can be called the invisible cornerstone supporting the efficient and stable operation of trucks.

Truck Snow Chains: Safety Guarantee on Icy and Snowy Roads

Truck Snow Chains: Safety Guarantee on Icy and Snowy Roads

Jul 28,2025

This article elaborates on truck snow chains, including their important role on icy and snowy roads, applicable scenarios, selection methods, installation steps, and usage precautions. It aims to provide references for truck drivers to drive safely in icy and snowy weather and reduce accidents caused by slippery roads.