About Us

Truck Tire Pressure Sensor: A Key Component for Safety and Efficiency

Views : 194

Update time : 2025-07-15 10:37:42

In the truck operation system, tires are the core supporting the weight of the entire vehicle, and the stability of tire pressure directly affects driving safety and operational efficiency. As the core component for real-time monitoring of tire pressure, truck tire pressure sensors are playing an increasingly prominent role.

I. Working Principles

Truck tire pressure sensors mainly achieve monitoring through two principles:

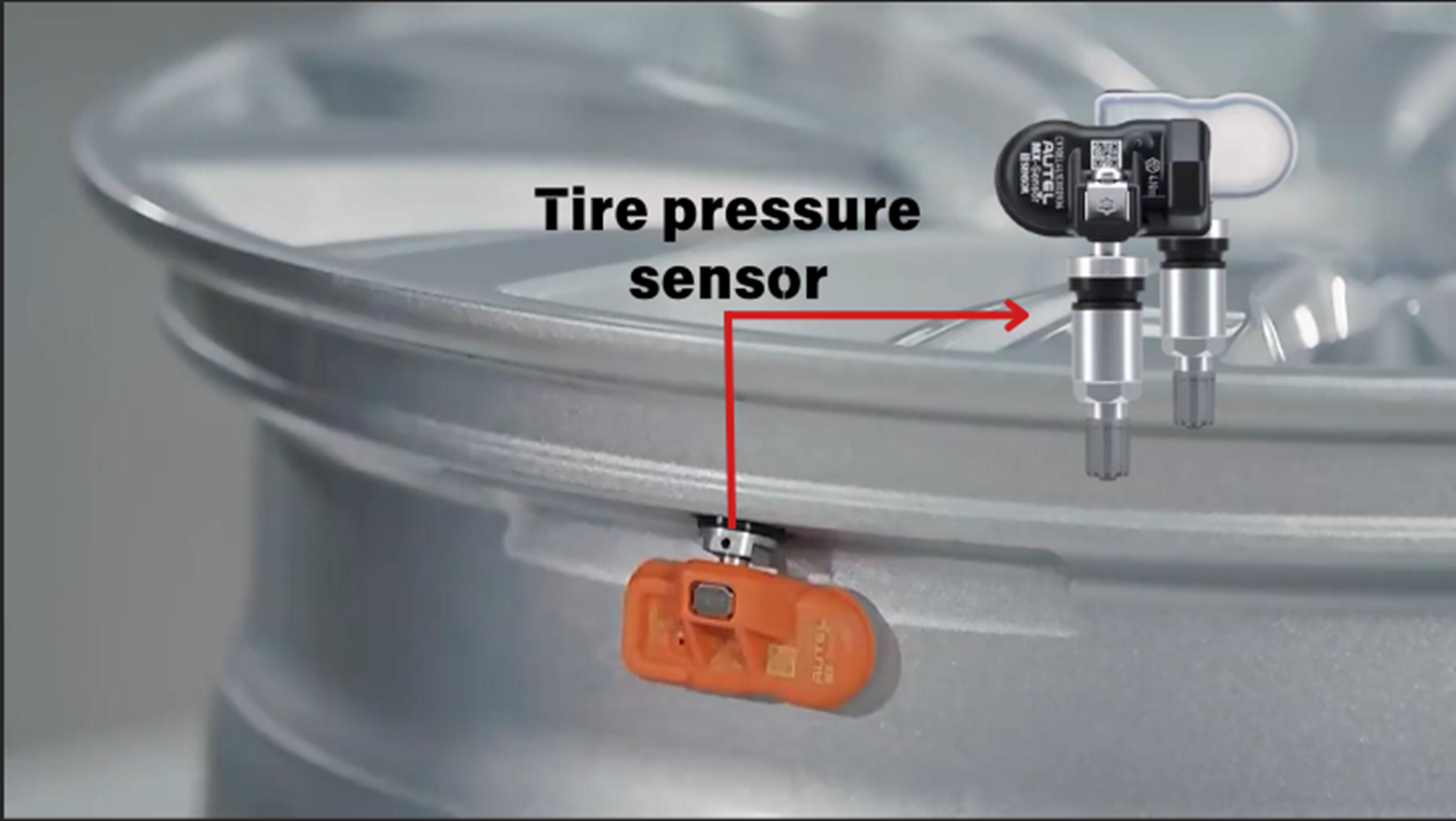

(I) Direct Type (Direct TPMS)

A pressure sensor is installed inside each tire, close to the valve. Based on the piezoresistive effect, the sensor converts tire pressure changes into electrical signals, which are wirelessly transmitted to the central receiving module via frequencies such as 433.92MHz, and the data is displayed on the screen in the cab. When the tire pressure exceeds the safety threshold, the system alarms immediately.

(II) Indirect Type (Indirect TPMS)

It infers tire pressure relying on wheel speed sensors. A decrease in tire pressure will reduce the rolling radius of the tire and increase its speed. The system judges abnormal air pressure by comparing the speed differences of each tire. However, it cannot obtain the actual tire pressure value, and it is susceptible to interference and misjudgment during rapid acceleration, braking or turning.

II. Types and Characteristics

(I) Built-in Type

Installed inside the tire (integrated with the valve or fixed separately), it has high stability, is not affected by the external environment, and the signal transmission is stable. However, installation and replacement require professional personnel to disassemble the tire, resulting in high maintenance costs.

(II) External Type

Installed outside the valve, connected by threads, it is easy to install and has low cost. But it is susceptible to environmental factors such as high temperature, severe cold and rain. Long-term use may reduce accuracy and service life, and data stability is slightly poor when driving at high speed.

III. Significance for Trucks

(I) Safety Assurance

Abnormal tire pressure is the main cause of tire blowouts: excessive air pressure will cause the tire temperature to rise sharply, while too low pressure will aggravate deformation, both of which will increase the risk of tire blowouts. The sensor monitors in real time and alarms, striving for processing time for the driver to avoid accidents.

(II) Improving Operational Efficiency

Proper tire pressure can reduce rolling resistance. When the tire pressure is 20% lower than the standard value, fuel consumption will increase by about 8%. The sensor can ensure normal tire pressure and reduce fuel consumption; at the same time, it reduces uneven tire wear, prolongs service life and reduces downtime.

IV. Mainstream Products and Performances in the Market

(I) Launch Tech

It launches two types: non-programmable Bluetooth and radio frequency. The Bluetooth type can obtain information through a mobile APP, which is easy to operate; the radio frequency type has high sensitivity and strong stability, suitable for scenarios with high precision requirements.

(II) Walker Products

The heavy-duty truck sensor adopts wheel-mounted installation, which reduces the risk of damage when replacing tires and lowers maintenance costs. It uses BLE technology, no programming is required, has a long battery life, and is compatible with mainstream TPMS tools.

(III) SNP739D Chip

A high-precision TPMS chip that can measure pressure, temperature, acceleration and voltage. The pressure range is 100-900/1900kPa, suitable for various models. It integrates multiple modules and has the advantages of high integration, low power consumption (sleep power consumption 0.25µA), high precision (pressure ±5kPa, temperature ±3℃) and so on.

V. Selection Points

- Measurement Range: It should cover the normal pressure range of truck tires and reserve redundancy to deal with fluctuations.

- Accuracy: The pressure accuracy should be above ±1.5psi, and the temperature accuracy should be about ±3℃ to ensure reliable data.

- Environmental Adaptability: It can work stably in the range of -40℃ to 125℃, and has waterproof, dustproof and anti-corrosion properties.

- Durability: Choose products made of high-quality materials that have passed strict tests to reduce the probability of failure.

- Cost-effectiveness: Comprehensive consideration of purchase, installation and maintenance costs, and balance the relationship between service life and cost to select cost-effective products.

- Compatibility: Match the interface of the existing on-board electronic system of the truck to ensure smooth data transmission.

Truck tire pressure sensors are key equipment to ensure safety and efficiency. With the advancement of technology, their performance will continue to improve. Fleet managers and vehicle owners should pay attention to their role, select them reasonably according to needs, and lay a solid foundation for the stable operation of trucks.

相关新闻

Revealing Three Little-Known Facts About Trucks

Revealing Three Little-Known Facts About Trucks

Aug 06,2025

This article presents three little-known facts about trucks, including that the cab can be flipped for engine maintenance, the rearview mirrors are equipped with defrosting and deicing functions, and the small tank next to the fuel tank is an urea tank which is crucial for environmental protection. It helps readers understand the secrets behind truck designs and functions.

Control Valve: The "Key Steward" in Truck Engines

Control Valve: The "Key Steward" in Truck Engines

Aug 05,2025

This article introduces the role of the control valve in the diesel pump, including controlling fuel quantity and stabilizing pressure; lists symptoms when it malfunctions, such as weakened power and increased fuel consumption; provides maintenance methods, and illustrates through cases that paying attention to the control valve can avoid unnecessary expenses.

Control Valve: The "Invisible Commander" of Truck Power

Control Valve: The "Invisible Commander" of Truck Power

Aug 05,2025

The control valve is an indispensable core regulating component in the truck power system. Although it hides inside the machinery and keeps a low profile, it relies on its powerful functions to precisely command the rhythm of power output, comprehensively ensure driving safety, and intelligently adapt to various working conditions. With sophisticated design techniques and durable material selection, it can achieve a perfect balance between power and efficiency in various complex scenarios, and can be called the invisible cornerstone supporting the efficient and stable operation of trucks.

Truck Snow Chains: Safety Guarantee on Icy and Snowy Roads

Truck Snow Chains: Safety Guarantee on Icy and Snowy Roads

Jul 28,2025

This article elaborates on truck snow chains, including their important role on icy and snowy roads, applicable scenarios, selection methods, installation steps, and usage precautions. It aims to provide references for truck drivers to drive safely in icy and snowy weather and reduce accidents caused by slippery roads.