About Us

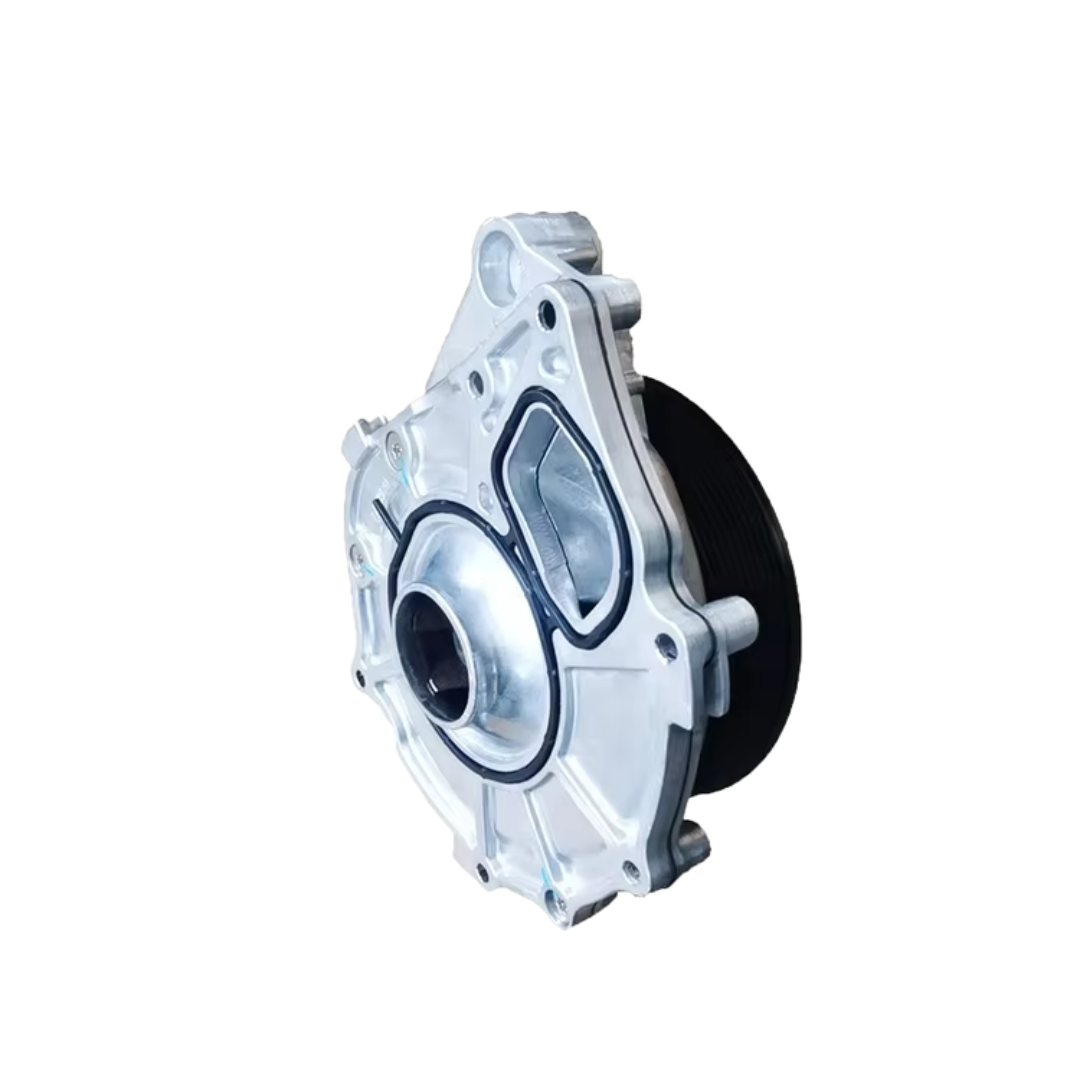

Worried About Engine Overheating During High - Speed Runs? This "Water - Cooled Heart" Has You Covered

Views : 308

Update time : 2025-06-26 11:06:51

In the complex mechanical system of a truck, the water pump acts like the heart, circulating coolant to maintain the engine's optimal temperature, which is crucial for the vehicle's safe operation and lifespan.

I. Core Working Principle

The truck water pump relies on centrifugal force to drive coolant circulation. When the engine runs, a belt or chain drives the impeller inside the water pump to rotate at high speed. Under the action of centrifugal force, the coolant is thrown out from the inlet, flowing through the engine's water jackets and radiators to dissipate heat, and then returns to the water pump. This cycle ensures the engine temperature remains stable between 80 - 95°C.

II. Common Types of Water Pumps and Their Characteristics

(1) Mechanical Water Pumps

Traditional mechanical water pumps are driven by the engine's crankshaft pulley. They feature a simple structure and high reliability. However, their fixed rotational speed means energy waste during low - load operation and potential insufficient heat dissipation during high - load operation.

(2) Electric Water Pumps

With the advancement of truck technology, electric water pumps are gaining popularity. Driven by an electric motor, they can be precisely controlled by the vehicle's ECU (Electronic Control Unit) according to the engine's real - time operating conditions, adjusting the rotational speed and coolant flow. This improves cooling efficiency and reduces energy consumption, but comes with higher costs and stricter requirements for the electronic control system.

(3) Hybrid Mechanical - Electric Water Pumps

These pumps combine the advantages of mechanical and electric types. Under normal conditions, they are driven mechanically, while the electric system kicks in during special scenarios (such as cold starts or high - load operations). This design balances reliability and intelligence, although it also increases maintenance difficulty and costs.

III. Common Faults and Symptoms

(1) Leakage

Water pump leakage is one of the most common issues, usually caused by worn - out seals (such as O - rings and water seals) or cracked pump housings. Serious leakage can lead to a drop in coolant level, engine overheating, and even "boiling," potentially damaging key engine components.

(2) Unusual Noises

Noises like "buzzing," "rustling," or metallic scraping sounds may indicate problems such as worn - out bearings, loose impellers, or foreign objects inside the pump. These noises are warning signs of potential failures.

(3) Performance Degradation

Corrosion or wear of the impeller, or damage to the keyway between the pump shaft and impeller, can impede coolant circulation. This results in symptoms like increased engine temperature, reduced power, and higher fuel consumption.

IV. Maintenance and Care

- Check Coolant Regularly: Monitor the coolant level, color, and clarity. Replace it every 2 - 3 years or every 40,000 - 60,000 kilometers to prevent degradation that could corrode the water pump.

- Inspect the Belt: For mechanical water pumps, pay attention to the wear and tension of the belt. Replace it if severely worn or incorrectly tensioned.

- Listen for Abnormal Sounds: If unusual noises occur, check immediately. Minor bearing wear can be addressed with lubrication, while severe issues require professional repair.

- Prevent Engine Overheating: Keep an eye on the engine temperature gauge during driving. Avoid prolonged high - load operation, and if overheating occurs, stop the vehicle promptly for inspection.

Related News

Revealing Three Little-Known Facts About Trucks

Revealing Three Little-Known Facts About Trucks

Aug 06,2025

This article presents three little-known facts about trucks, including that the cab can be flipped for engine maintenance, the rearview mirrors are equipped with defrosting and deicing functions, and the small tank next to the fuel tank is an urea tank which is crucial for environmental protection. It helps readers understand the secrets behind truck designs and functions.

Control Valve: The "Key Steward" in Truck Engines

Control Valve: The "Key Steward" in Truck Engines

Aug 05,2025

This article introduces the role of the control valve in the diesel pump, including controlling fuel quantity and stabilizing pressure; lists symptoms when it malfunctions, such as weakened power and increased fuel consumption; provides maintenance methods, and illustrates through cases that paying attention to the control valve can avoid unnecessary expenses.

Control Valve: The "Invisible Commander" of Truck Power

Control Valve: The "Invisible Commander" of Truck Power

Aug 05,2025

The control valve is an indispensable core regulating component in the truck power system. Although it hides inside the machinery and keeps a low profile, it relies on its powerful functions to precisely command the rhythm of power output, comprehensively ensure driving safety, and intelligently adapt to various working conditions. With sophisticated design techniques and durable material selection, it can achieve a perfect balance between power and efficiency in various complex scenarios, and can be called the invisible cornerstone supporting the efficient and stable operation of trucks.

Truck Snow Chains: Safety Guarantee on Icy and Snowy Roads

Truck Snow Chains: Safety Guarantee on Icy and Snowy Roads

Jul 28,2025

This article elaborates on truck snow chains, including their important role on icy and snowy roads, applicable scenarios, selection methods, installation steps, and usage precautions. It aims to provide references for truck drivers to drive safely in icy and snowy weather and reduce accidents caused by slippery roads.