About Us

Truck Filters: Key Components to Ensure the Efficient Operation of Trucks

Views : 238

Update time : 2025-06-25 18:09:13

In the structure of a truck, although filters are small components, they play a crucial role in maintaining the normal operation of the truck and safeguard its core systems. The following is professional knowledge about truck filters.

I. Types and Functions of Truck Filters

(1) Air Filter - The "Lungs" of the Engine

The air filter is the core of the intake system. It can filter out impurities such as dust and sand, preventing the reduction of engine combustion efficiency and potential damage, and reducing the early wear of components like cylinders. Structurally, it is divided into dry - type and wet - type (oil - immersed and oil - bath types). Trucks operating in harsh conditions often use multi - stage filters. Its filtration mechanisms include diffusion, interception, inertia, screening, and electrostatic effects.

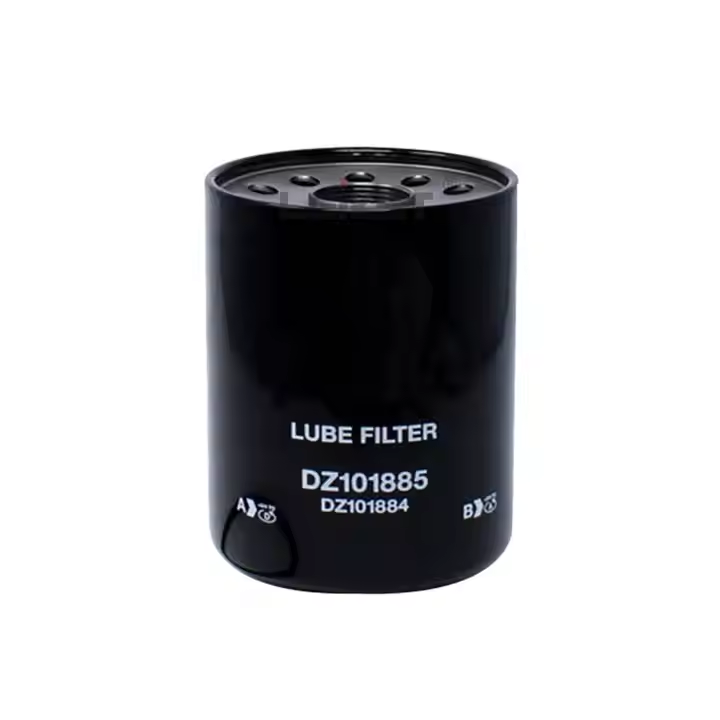

(2) Oil Filter - The "Kidneys" of the Engine

Located in the engine lubrication system, it can remove impurities such as dust and metal particles from the engine oil. The engine lubrication system is usually equipped with oil strainers, coarse filters, and fine filters, which are connected in parallel or series to the main oil passage. Spin - on filters are widely used. They can ensure that the engine oil flowing to the moving parts of the engine is clean, thus extending the service life of these components.

(3) Fuel Filter - The "Scavenger" of the Fuel System

It is connected in series to the pipeline between the fuel pump and the intake port of the throttle body. Its function is to filter out solid impurities and moisture, protecting the engine. For engines meeting the National III emission standard and above, the fuel system is equipped with a diesel coarse filter and a diesel fine filter, which filter out large and small particles respectively. The water - oil separator, which separates water from oil using the density difference, is an important component of the system.

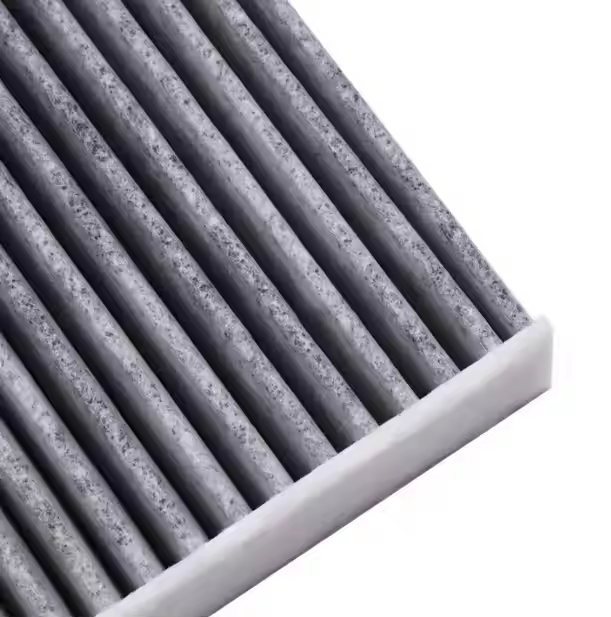

(4) Air - Conditioner Filter - The "Air Purification Guardian" in the Cab

It can filter out pollutants such as dust and pollen in the air entering the cab, safeguarding the health of the driver and enhancing the driving experience.

II. Replacement Cycles of Filters

(1) Air Filter

Generally, it should be inspected or replaced every 15,000 to 30,000 kilometers. In dusty environments, the replacement cycle should be shortened. When the engine's power decreases or fuel consumption increases, it should be inspected in a timely manner.

(2) Oil Filter

It is usually replaced simultaneously with the engine oil, generally every 5,000 to 10,000 kilometers. Refer to the vehicle maintenance manual for specific details.

(3) Fuel Filter

The replacement cycle is generally 20,000 to 40,000 kilometers. In areas with poor fuel quality, the cycle should be shortened.

(4) Air - Conditioner Filter

It is recommended to inspect it every 10,000 to 15,000 kilometers. When the air volume of the air conditioner decreases or the air quality deteriorates, it should be replaced in a timely manner.

相关新闻

Revealing Three Little-Known Facts About Trucks

Revealing Three Little-Known Facts About Trucks

Aug 06,2025

This article presents three little-known facts about trucks, including that the cab can be flipped for engine maintenance, the rearview mirrors are equipped with defrosting and deicing functions, and the small tank next to the fuel tank is an urea tank which is crucial for environmental protection. It helps readers understand the secrets behind truck designs and functions.

Control Valve: The "Key Steward" in Truck Engines

Control Valve: The "Key Steward" in Truck Engines

Aug 05,2025

This article introduces the role of the control valve in the diesel pump, including controlling fuel quantity and stabilizing pressure; lists symptoms when it malfunctions, such as weakened power and increased fuel consumption; provides maintenance methods, and illustrates through cases that paying attention to the control valve can avoid unnecessary expenses.

Control Valve: The "Invisible Commander" of Truck Power

Control Valve: The "Invisible Commander" of Truck Power

Aug 05,2025

The control valve is an indispensable core regulating component in the truck power system. Although it hides inside the machinery and keeps a low profile, it relies on its powerful functions to precisely command the rhythm of power output, comprehensively ensure driving safety, and intelligently adapt to various working conditions. With sophisticated design techniques and durable material selection, it can achieve a perfect balance between power and efficiency in various complex scenarios, and can be called the invisible cornerstone supporting the efficient and stable operation of trucks.

Truck Snow Chains: Safety Guarantee on Icy and Snowy Roads

Truck Snow Chains: Safety Guarantee on Icy and Snowy Roads

Jul 28,2025

This article elaborates on truck snow chains, including their important role on icy and snowy roads, applicable scenarios, selection methods, installation steps, and usage precautions. It aims to provide references for truck drivers to drive safely in icy and snowy weather and reduce accidents caused by slippery roads.