About Us

How many types of trailer suspensions have you seen? Don't just stick to leaf springs.

Views : 241

Update time : 2025-06-18 11:34:47

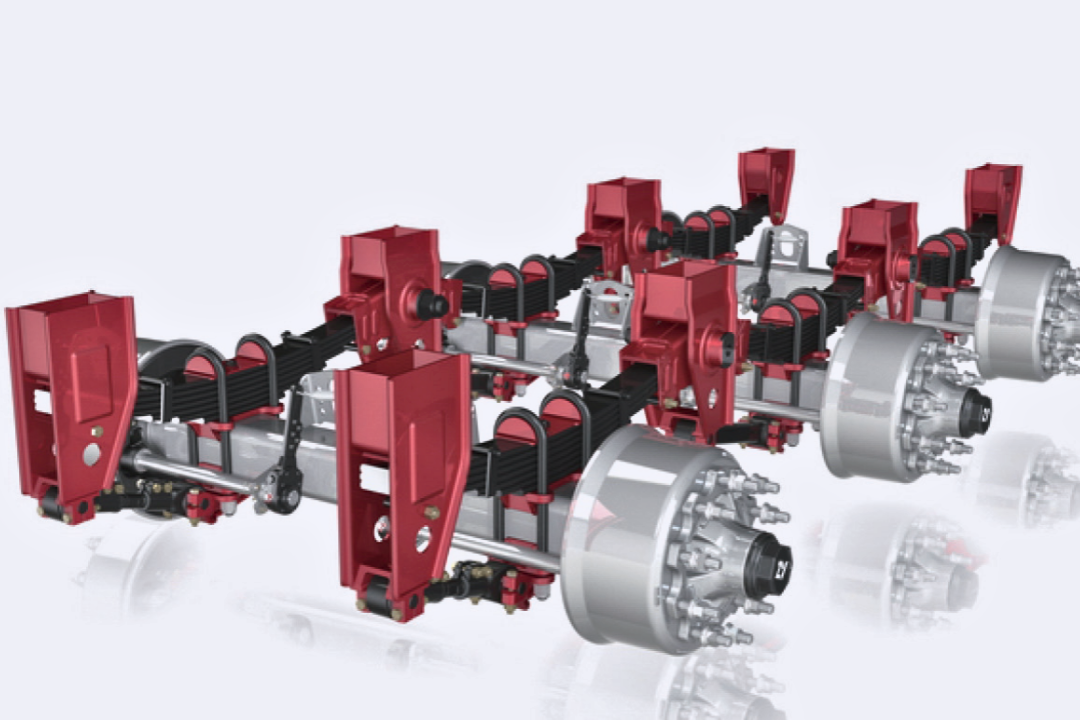

Trailer Air Suspensions: Classification, Advantages and Application Scenarios Analysis

I. Key Points of Air Suspensions

Definition: Utilizing air springs as elastic components, an air suspension system is composed of airbags, air compressors, control units, etc. It achieves shock absorption through the compressibility of gas and can automatically adjust the vehicle body height according to road conditions.

Core Advantages:

- Excellent shock absorption performance, reducing cargo damage rate by over 30%;

- Height - adjustable, well - suited for drop - and - hook transportation and platform loading/unloading;

- Lightweight design, reducing weight by 15% - 20% compared with leaf springs;

- Minimizes wear of chassis components and extends tire lifespan by 20%;

- Reduces air resistance, saving 5% - 8% in fuel consumption.

II. Classification and Characteristics of Air Suspensions

Classification by Structure: American - style VS European - style

European - style air suspensions adopt a forged flexible arm structure, usually designed as single - piece or multi - piece, and directly forged, belonging to flexible components. This design endows them with strong load - bearing capacity, capable of handling a single - axle load of 13 tons or more. The curved shape of the guiding arms allows the airbags to have a long shock - absorption stroke of over 200mm, resulting in excellent shock - absorption performance. They are suitable for trunk logistics, heavy - load transportation and other scenarios. However, they come with a relatively high cost, more complex structure, and higher maintenance difficulty and cost in case of failure.

American - style air suspensions feature a rigid "I - beam" - type fastening design, which are rigid components. The structure is more compact, theoretically 10% lighter than European - style suspensions, and more cost - effective. Moreover, the larger contact area between the guiding arms and axles provides better lateral support, ensuring good vehicle stability. They are ideal for standard - load transportation, highway express delivery and other working conditions. Nevertheless, due to their shorter shock - absorption stroke, their adaptability to complex road conditions is relatively weak.

Classification by the Number of Airbags

Common configurations for a single axle include 2 - airbag, 4 - airbag, and 8 - airbag setups. In terms of performance, the number of airbags is positively correlated with shock - absorption effect and load - bearing capacity. That is, 8 - airbag suspensions outperform 4 - airbag ones, which in turn are better than 2 - airbag ones. In terms of cost, the more airbags there are, the higher the purchase and maintenance costs. The cost of an 8 - airbag system is approximately 40% higher than that of a 2 - airbag system.

III. Decision - making: Is an Air Suspension Really for You?

Key Considerations:

- Cost Threshold: The purchase cost of air suspensions is 30% - 50% higher than that of leaf springs, and maintenance requires professional equipment such as air compressor inspection.

- Working Condition Adaptability:

✅ Recommended Scenarios: Trunk logistics, express delivery, transportation of high - value - added goods (such as precision equipment), drop - and - hook transportation;

❌ Cautionary Scenarios: Heavy - load mining operations, complex unpaved roads, transportation without fixed cargo sources.

Conclusion: Air suspensions have significant advantages in terms of lightweight design, comfort, and economy. However, rational selection should be made based on transportation scenarios and cost budgets. Traditional leaf springs still hold an irreplaceable position in extreme - load and harsh - condition operations.

Related News

Revealing Three Little-Known Facts About Trucks

Revealing Three Little-Known Facts About Trucks

Aug 06,2025

This article presents three little-known facts about trucks, including that the cab can be flipped for engine maintenance, the rearview mirrors are equipped with defrosting and deicing functions, and the small tank next to the fuel tank is an urea tank which is crucial for environmental protection. It helps readers understand the secrets behind truck designs and functions.

Control Valve: The "Key Steward" in Truck Engines

Control Valve: The "Key Steward" in Truck Engines

Aug 05,2025

This article introduces the role of the control valve in the diesel pump, including controlling fuel quantity and stabilizing pressure; lists symptoms when it malfunctions, such as weakened power and increased fuel consumption; provides maintenance methods, and illustrates through cases that paying attention to the control valve can avoid unnecessary expenses.

Control Valve: The "Invisible Commander" of Truck Power

Control Valve: The "Invisible Commander" of Truck Power

Aug 05,2025

The control valve is an indispensable core regulating component in the truck power system. Although it hides inside the machinery and keeps a low profile, it relies on its powerful functions to precisely command the rhythm of power output, comprehensively ensure driving safety, and intelligently adapt to various working conditions. With sophisticated design techniques and durable material selection, it can achieve a perfect balance between power and efficiency in various complex scenarios, and can be called the invisible cornerstone supporting the efficient and stable operation of trucks.

Truck Snow Chains: Safety Guarantee on Icy and Snowy Roads

Truck Snow Chains: Safety Guarantee on Icy and Snowy Roads

Jul 28,2025

This article elaborates on truck snow chains, including their important role on icy and snowy roads, applicable scenarios, selection methods, installation steps, and usage precautions. It aims to provide references for truck drivers to drive safely in icy and snowy weather and reduce accidents caused by slippery roads.